| Availability: | |

|---|---|

| Quantity: | |

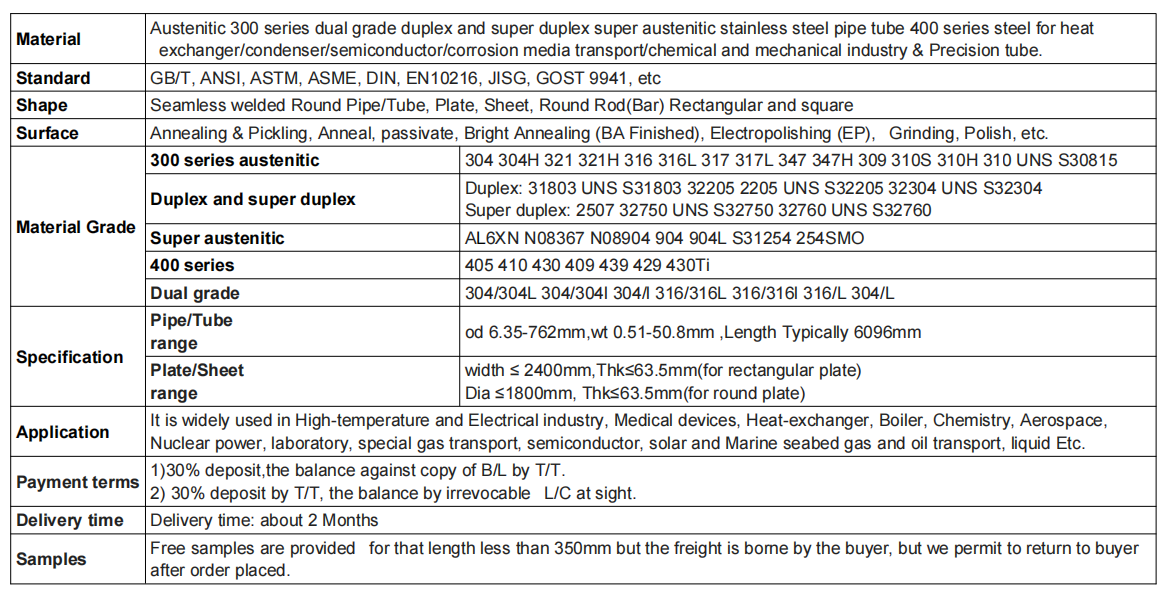

Type: Austenitic-ferritic duplex stainless steel

UNS number: S31803

Excellent Corrosion Resistance:

Resistance to Chloride Stress Corrosion Cracking: This is far superior to 304/316 austenitic stainless steel and is one of its most important advantages.

Resistance to Pitting and Crevice Corrosion: Due to its higher Cr, Mo, and N contents and PREN values, its performance is superior to 316L and approaches that of super-austenitic stainless steels such as 904L.

Resistance to Uniform Corrosion: It performs well in a variety of acidic and alkaline environments, generally superior to 316L.

High Strength:

Yield Strength: Approximately twice that of 304/316 austenitic stainless steel (typically ≥ 450 MPa).

Tensile Strength: This is also significantly higher than that of austenitic stainless steel (typically ≥ 620 MPa).

Advantages: This allows for thinner wall designs, reducing weight and cost (particularly in pressure vessels and structural components).

Good Toughness: While not as good as austenitic stainless steel, it is sufficiently tough at most engineering application temperatures (including sub-zero temperatures). Good Weldability: Ferritic stainless steels offer superior weldability compared to austenitic stainless steels. They are typically welded using similar methods as austenitic stainless steels (TIG, MIG, SMAW, SAW), but require stricter control of heat input and interpass temperature, and the use of matching or higher-alloyed consumables (such as ER2209) to maintain phase equilibrium and corrosion resistance in the weld area.

Good Fatigue Strength: This is due to its high strength.

Thermal Conductivity: Higher than austenitic stainless steels, lower than carbon steels.

The Coefficient of Thermal Expansion: Lower than austenitic stainless steels, closer to carbon steels, facilitating dissimilar steel welding and minimizing thermal deformation.

S31803 (alternative to S32205 / 2205) is a duplex stainless steel with exceptional performance. It offers a perfect combination of high strength, excellent resistance to chloride stress corrosion cracking, good resistance to pitting and crevice corrosion, and acceptable toughness and weldability. This makes it a highly cost-effective choice for applications requiring both corrosion and high strength, such as the oil and gas, chemical and petrochemical industries, offshore engineering, and energy and environmental protection. It is often used as an upgrade to 316L or as a replacement for 904L when strength requirements are met.

The chemical composition (UNS S31803):

C | Si | Mn | P | S | Ni | Cr | Mo | N |

≤0.03 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.02 | 4.5-6.5 | 21.0-23.0 | 2.5-3.5 | 0.08-0.20 |

Mechanical properties

tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) | |

≥620 | ≥450 | ≥25 |

Density: 7.98g/cm³

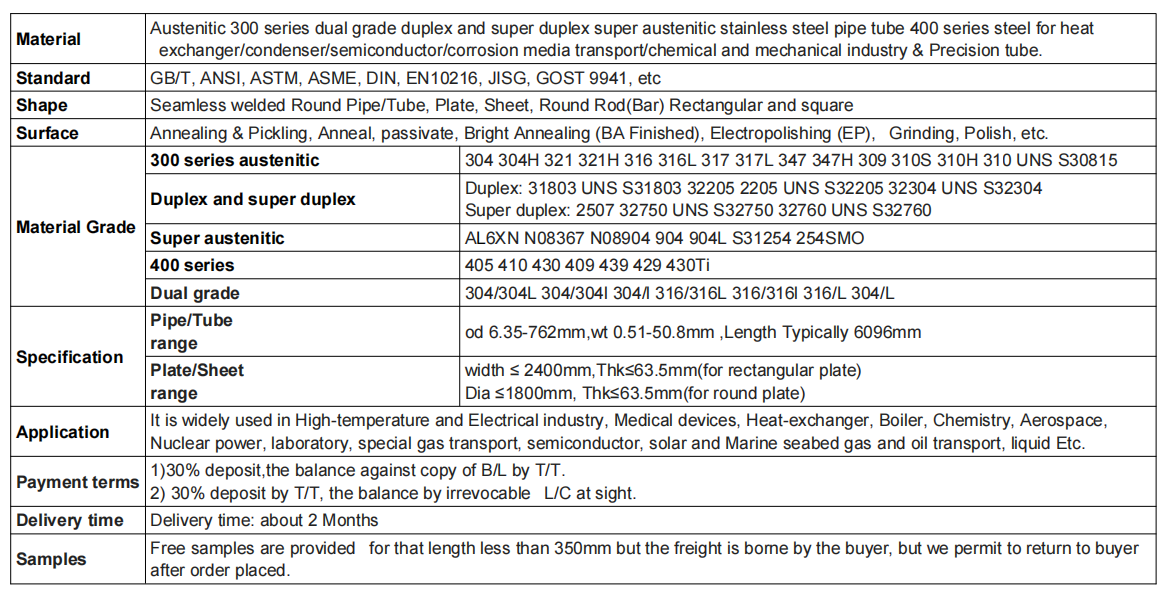

Type: Austenitic-ferritic duplex stainless steel

UNS number: S31803

Excellent Corrosion Resistance:

Resistance to Chloride Stress Corrosion Cracking: This is far superior to 304/316 austenitic stainless steel and is one of its most important advantages.

Resistance to Pitting and Crevice Corrosion: Due to its higher Cr, Mo, and N contents and PREN values, its performance is superior to 316L and approaches that of super-austenitic stainless steels such as 904L.

Resistance to Uniform Corrosion: It performs well in a variety of acidic and alkaline environments, generally superior to 316L.

High Strength:

Yield Strength: Approximately twice that of 304/316 austenitic stainless steel (typically ≥ 450 MPa).

Tensile Strength: This is also significantly higher than that of austenitic stainless steel (typically ≥ 620 MPa).

Advantages: This allows for thinner wall designs, reducing weight and cost (particularly in pressure vessels and structural components).

Good Toughness: While not as good as austenitic stainless steel, it is sufficiently tough at most engineering application temperatures (including sub-zero temperatures). Good Weldability: Ferritic stainless steels offer superior weldability compared to austenitic stainless steels. They are typically welded using similar methods as austenitic stainless steels (TIG, MIG, SMAW, SAW), but require stricter control of heat input and interpass temperature, and the use of matching or higher-alloyed consumables (such as ER2209) to maintain phase equilibrium and corrosion resistance in the weld area.

Good Fatigue Strength: This is due to its high strength.

Thermal Conductivity: Higher than austenitic stainless steels, lower than carbon steels.

The Coefficient of Thermal Expansion: Lower than austenitic stainless steels, closer to carbon steels, facilitating dissimilar steel welding and minimizing thermal deformation.

S31803 (alternative to S32205 / 2205) is a duplex stainless steel with exceptional performance. It offers a perfect combination of high strength, excellent resistance to chloride stress corrosion cracking, good resistance to pitting and crevice corrosion, and acceptable toughness and weldability. This makes it a highly cost-effective choice for applications requiring both corrosion and high strength, such as the oil and gas, chemical and petrochemical industries, offshore engineering, and energy and environmental protection. It is often used as an upgrade to 316L or as a replacement for 904L when strength requirements are met.

The chemical composition (UNS S31803):

C | Si | Mn | P | S | Ni | Cr | Mo | N |

≤0.03 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.02 | 4.5-6.5 | 21.0-23.0 | 2.5-3.5 | 0.08-0.20 |

Mechanical properties

tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) | |

≥620 | ≥450 | ≥25 |

Density: 7.98g/cm³

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.