| Availability: | |

|---|---|

| Quantity: | |

S32205 (UNS S32205 / EN 1.4462) is an important duplex stainless steel that combines the advantages of austenitic and ferritic stainless steels.

The yield strength of S32205 is more than twice that of standard austenitic stainless steels (such as 304 and 316).

This means that thinner wall thicknesses can be used for the same design stress, reducing weight and cost (due to reduced material usage).

It also offers excellent fatigue strength and wear resistance.

Resistance to chloride stress corrosion cracking: This is one of its most significant advantages. In chloride-containing environments (such as seawater, chlorine bleach, salt spray, and chemical process media), its SCC resistance far exceeds that of 304L and 316L austenitic stainless steels.

Resistance to pitting and crevice corrosion: It has a high pitting corrosion resistance equivalent value. The PREN value is typically around 33-35 (PREN = %Cr + 3.3 × %Mo + 16 × %N), higher than that of 316L (~24-26) and approaching or even exceeding that of 317L and 904L. This makes it excellent in seawater, chlorinated water, and chemical media.

Excellent Uniform Corrosion Resistance: It offers excellent corrosion resistance in a variety of acids (such as sulfuric acid, phosphoric acid, and organic acids), alkalis, and saline solutions, outperforming 316L.

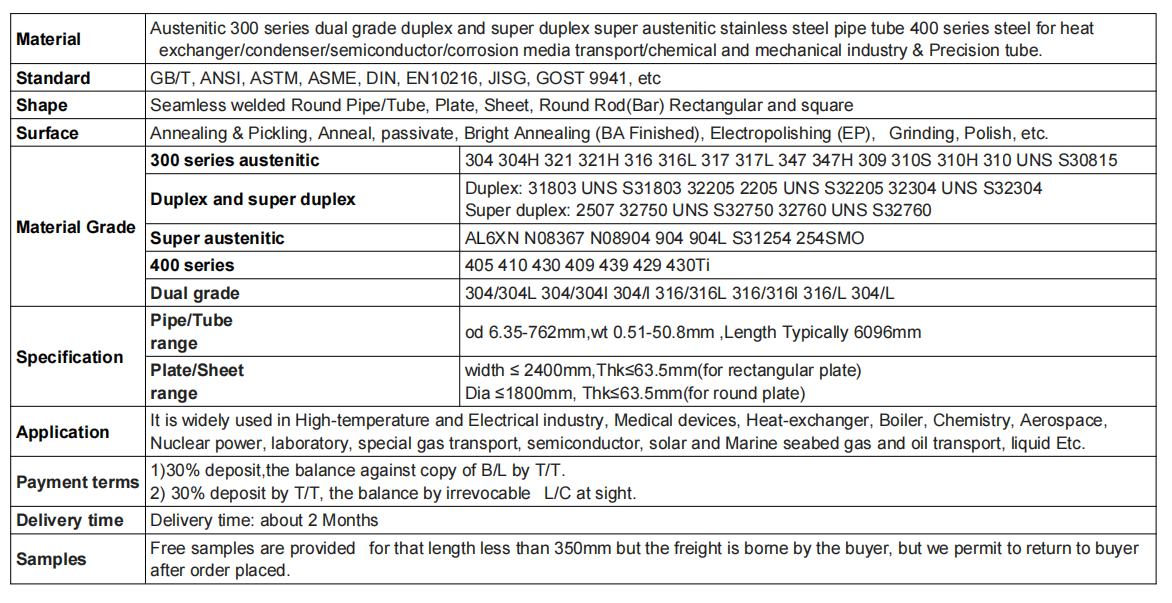

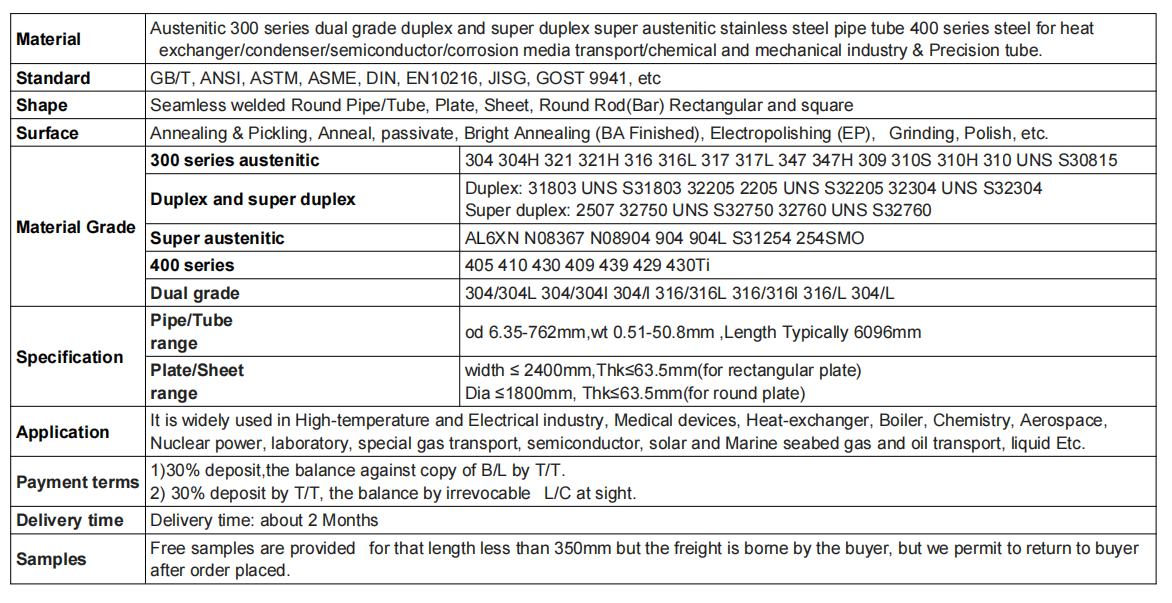

Chemical composition

Mo | Cr | Ni | Mn | C | Si | P | S | N |

3.0-3.5 | 22-23 | 4.5-6.5 | ≤2.00 | ≤0.03 | ≤1.00 | ≤0.03 | ≤0.02 | 0.14-0.20 |

Mechanical properties

tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) |

≥620 | ≥450 | ≥25 |

Density: 7.98 g/cm3

S32205 (UNS S32205 / EN 1.4462) is an important duplex stainless steel that combines the advantages of austenitic and ferritic stainless steels.

The yield strength of S32205 is more than twice that of standard austenitic stainless steels (such as 304 and 316).

This means that thinner wall thicknesses can be used for the same design stress, reducing weight and cost (due to reduced material usage).

It also offers excellent fatigue strength and wear resistance.

Resistance to chloride stress corrosion cracking: This is one of its most significant advantages. In chloride-containing environments (such as seawater, chlorine bleach, salt spray, and chemical process media), its SCC resistance far exceeds that of 304L and 316L austenitic stainless steels.

Resistance to pitting and crevice corrosion: It has a high pitting corrosion resistance equivalent value. The PREN value is typically around 33-35 (PREN = %Cr + 3.3 × %Mo + 16 × %N), higher than that of 316L (~24-26) and approaching or even exceeding that of 317L and 904L. This makes it excellent in seawater, chlorinated water, and chemical media.

Excellent Uniform Corrosion Resistance: It offers excellent corrosion resistance in a variety of acids (such as sulfuric acid, phosphoric acid, and organic acids), alkalis, and saline solutions, outperforming 316L.

Chemical composition

Mo | Cr | Ni | Mn | C | Si | P | S | N |

3.0-3.5 | 22-23 | 4.5-6.5 | ≤2.00 | ≤0.03 | ≤1.00 | ≤0.03 | ≤0.02 | 0.14-0.20 |

Mechanical properties

tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) |

≥620 | ≥450 | ≥25 |

Density: 7.98 g/cm3

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.