Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

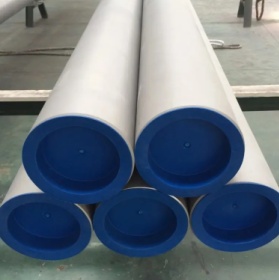

In high-precision industrial environments, especially those linked to aerospace manufacturing and advanced engineering, material reliability is not just a preference—it is a necessity. One material that consistently meets these demanding requirements is the TUV aerospace industry stainless steel tube. Known for its strict certification standards, exceptional mechanical strength, and long-term durability, this type of stainless steel tubing has become a critical component in many industrial systems where performance, safety, and consistency matter most.

For factories and industrial users who are new to aerospace-grade stainless steel tubing, understanding what makes a TUV aerospace industry stainless steel tube different from standard tubing is an essential first step toward making better procurement and engineering decisions. These tubes are not only designed to withstand extreme temperatures, pressures, and corrosive environments, but they are also manufactured under tightly controlled processes to ensure precise dimensions, uniform surface quality, and traceable material composition.

In this beginner’s guide, we will explain what TUV aerospace industry stainless steel tubes are, how they are produced, where they are used, and why they are increasingly adopted in demanding industrial applications beyond aerospace. Whether your factory is involved in high-precision manufacturing, fluid transmission systems, or equipment that requires absolute material consistency, this article will help you understand how TUV-certified stainless steel tubes can enhance reliability, safety, and long-term performance.

A TUV aerospace industry stainless steel tube is a high-performance stainless steel tube that has been manufactured and tested according to strict aerospace-level standards and verified by TUV, a globally recognized certification organization. The TUV certification ensures that the tubing meets rigorous requirements for chemical composition, mechanical strength, dimensional accuracy, and surface quality.

Unlike conventional stainless steel tubing used in general construction or low-pressure systems, aerospace-grade tubing must deliver consistent performance under extreme conditions. These tubes are typically produced from premium stainless steel grades such as 304, 316L, 321, or other high-alloy compositions designed to resist corrosion, fatigue, and thermal stress.

Key characteristics of TUV aerospace industry stainless steel tubes include:

High tensile strength and pressure resistance

Excellent corrosion and oxidation resistance

Tight dimensional tolerances

Smooth internal and external surfaces

Full material traceability and quality documentation

TUV certification is far more than a simple quality label—it represents strict compliance with internationally recognized testing, inspection, and quality control standards. For factories and industrial users, TUV certification provides a high level of assurance that stainless steel tubes will perform consistently and safely under demanding conditions. In sectors such as aerospace, energy, chemical processing, and high-precision manufacturing, even minor material defects can lead to system failures, production downtime, or safety risks. TUV certification helps eliminate these uncertainties by verifying that every production batch meets clearly defined technical and performance requirements.

One of the key advantages of TUV-certified stainless steel tubes is reduced technical risk. Each tube undergoes multiple layers of testing and inspection before entering the supply chain. This ensures stable mechanical performance, accurate dimensions, and reliable corrosion resistance. For factory operations that depend on uninterrupted production and long-term system stability, this level of quality control is critical. It also simplifies procurement decisions, as buyers can trust that the product meets consistent standards across different production runs.

TUV-certified stainless steel tubes typically undergo the following core inspections and tests:

Chemical composition analysis

Confirms that alloy elements such as chromium, nickel, and molybdenum meet specified ratios for corrosion resistance and mechanical strength.

Mechanical property testing

Measures tensile strength, yield strength, elongation, and hardness to ensure structural integrity under pressure and vibration.

Dimensional inspection

Verifies outer diameter, inner diameter, wall thickness, and straightness to maintain tight tolerances required for precision assembly.

Surface defect evaluation

Identifies cracks, inclusions, or surface irregularities that could weaken performance or contaminate fluids.

Pressure and fatigue testing

Ensures the tube can withstand long-term cyclic stress and high internal pressure without failure.

Together, these testing steps guarantee that each TUV aerospace industry stainless steel tube meets defined aerospace-grade requirements before it is approved for industrial use.

The superior performance of TUV aerospace industry stainless steel tubes comes from a combination of high-grade materials and precision manufacturing. These properties make them suitable for demanding industrial environments where reliability is non-negotiable.

Property | Description |

Corrosion Resistance | Resists oxidation, chemicals, and moisture in harsh environments |

Mechanical Strength | Maintains structural integrity under high pressure and vibration |

Dimensional Accuracy | Ensures tight tolerances for precision assembly |

Surface Finish | Smooth surfaces reduce friction and contamination risks |

Temperature Stability | Performs reliably across wide temperature ranges |

Long-Term Durability | Designed for extended service life with minimal maintenance |

These properties are particularly valuable in systems that operate continuously or under extreme environmental conditions. Whether used in fluid transmission, high-pressure pipelines, or precision mechanical systems, TUV-certified tubes deliver consistent and predictable performance over long periods.

The production of TUV aerospace industry stainless steel tubes follows a multi-step process designed to ensure dimensional precision, material consistency, and long-term durability.

Premium stainless steel billets are selected based on strict chemical composition and mechanical performance requirements. Only high-purity raw materials are used to ensure consistent alloy structure and corrosion resistance.

Tubes are formed using advanced cold-drawing or rolling techniques. These processes improve dimensional accuracy and surface smoothness while enhancing mechanical strength through controlled deformation.

Controlled heat treatment is applied to relieve internal stresses and optimize material properties. This step improves strength, flexibility, and resistance to fatigue and thermal cycling.

Polishing, pickling, or passivation is used to enhance corrosion resistance and achieve a clean, smooth surface finish. This is especially important for fluid and gas transmission systems where contamination risks must be minimized.

Each production batch undergoes comprehensive inspection and testing to confirm compliance with TUV aerospace standards. This final verification step ensures that only qualified tubes enter the industrial supply chain.

Although originally developed for aerospace systems, TUV aerospace industry stainless steel tubes are widely used in other demanding industrial environments.

Factories producing advanced machinery rely on these tubes for hydraulic systems, pneumatic lines, and cooling circuits where reliability and dimensional consistency are essential.

Corrosion-resistant stainless steel tubing is ideal for transporting aggressive fluids, gases, and solvents in chemical plants.

Power stations and renewable energy systems use aerospace-grade tubing for heat exchangers, pressure systems, and fuel delivery lines.

In cleanroom environments, smooth internal surfaces and low contamination risk make these tubes suitable for precision fluid and gas systems.

Choosing TUV aerospace industry stainless steel tubes delivers both technical and operational advantages:

Reduced risk of leakage and failure

Longer service life

Lower maintenance costs

Higher system reliability

Improved safety compliance

Consistent material quality across batches

When selecting tubing for your factory or industrial system, consider the following factors:

Selection Factor | Why It Matters |

Steel Grade | Determines corrosion resistance and mechanical strength |

Outer and Inner Diameter | Affects flow rate and installation compatibility |

Wall Thickness | Influences pressure resistance |

Surface Finish | Impacts cleanliness and friction |

Certification Documents | Confirms TUV compliance and material traceability |

For factories operating in high-stress, high-precision environments, standard tubing often falls short. Aerospace-grade stainless steel tubes offer a proven solution for applications where safety, accuracy, and long-term stability are non-negotiable.

By adopting TUV aerospace industry stainless steel tubes, industrial users gain access to a premium material solution that enhances equipment reliability, reduces downtime, and supports consistent production quality.

Understanding TUV aerospace industry stainless steel tubes is the first step toward building more reliable, efficient, and durable industrial systems. These tubes offer unmatched performance in terms of strength, corrosion resistance, and dimensional precision, making them ideal for aerospace, energy, chemical processing, and advanced manufacturing applications.

At ZheJiang GaoSheng Pipe Industry Co., LTD., we specialize in manufacturing high-quality TUV aerospace industry stainless steel tubes tailored to industrial and factory requirements. Our production processes focus on precision, consistency, and long-term reliability, ensuring that your systems operate safely and efficiently. If you are looking for dependable stainless steel tubing solutions for demanding applications, we welcome you to contact us and explore how our products can support your production needs.

1. What is a TUV aerospace industry stainless steel tube?

It is a high-performance stainless steel tube certified by TUV to meet aerospace-level quality and safety standards.

2. Are TUV aerospace industry stainless steel tubes only used in aerospace?

No. They are widely used in industrial manufacturing, chemical processing, energy systems, and precision equipment.

3. What makes these tubes different from standard stainless steel tubes?

They offer tighter tolerances, higher durability, better surface quality, and full certification traceability.

4. How do I choose the right tube for my factory application?

Consider the steel grade, diameter, wall thickness, surface finish, and required certification standards.