Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

We will delve into a detailed comparison of two heavyweight nickel alloys: Monel Alloy 400 and Hastelloy C276. Widely used in the chemical processing industry, they are highly regarded for their mechanical properties and corrosion resistance. However, they are fundamentally different alloys with distinct alloying elements. How do these differences impact mechanical and corrosion-resistant properties, as well as the ease of processing and fabrication? Let's find out.

Monel Alloy 400 is certified under the British Standard BS3076 (NA13) and the American Standard ASTM B164 (N04400). Hastelloy C276 complies with the American Standard ASTM B574 (N10276). Both can meet the requirements of NACE MR-0175, ensuring strict corrosion resistance in harsh environments.

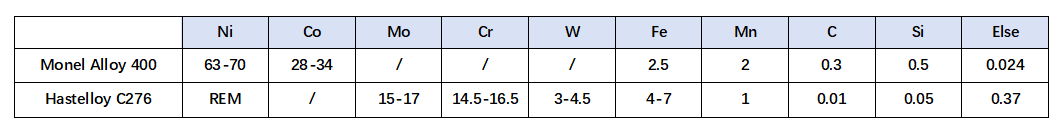

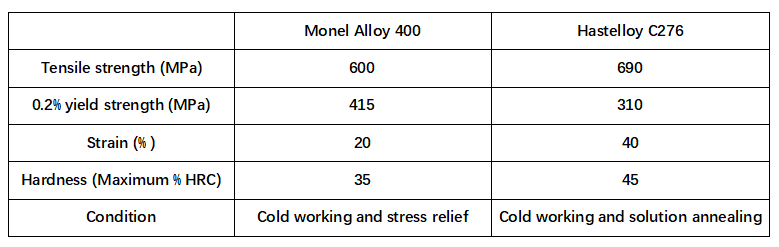

Monel Alloy 400 relies heavily on the addition of copper in its composition, whereas Hastelloy C276 contains molybdenum, chromium, and tungsten. These elements provide stronger solution strengthening, resulting in higher tensile strength. The stricter control of impurities such as silicon and carbon in Hastelloy C276 improves its weldability. However, as always, there is no free lunch—this also increases production costs.

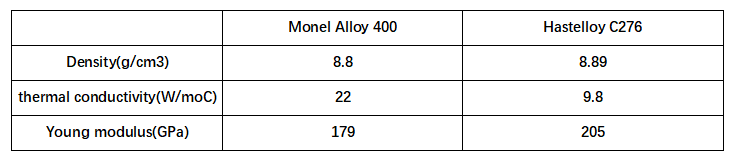

The alloying elements in Hastelloy C276 provide higher tensile strength and hardness, making it suitable for high-temperature applications where structural stability is critical. At elevated temperatures, the microstructure of any alloy becomes more unstable, which can lead to the precipitation of harmful phases, compromising the material. The careful use of additives in Hastelloy C276 mitigates this risk.

Both alloys are highly praised for their corrosion resistance, but their protective effects vary under different conditions. The copper content in Monel Alloy 400 offers excellent corrosion resistance in oxidizing environments at room temperature, but it diminishes at high temperatures. In contrast, the chromium and molybdenum in Hastelloy C276 provide strong oxidation resistance even at high temperatures and enhance protection in reducing atmospheres.

Both alloys are extensively used in the chemical processing industry. However, their applications differ:

Monel Alloy 400: Suitable for valves, pumps, gasoline and freshwater tanks, process vessels, marine fittings, and heat exchangers.

Hastelloy C276: Suitable for heat exchangers, reaction vessels, evaporators, and even for the recovery of "sour" natural gas.

Monel Alloy 400 and Hastelloy C276 each offer outstanding mechanical properties and corrosion resistance, with specific strengths tailored to different environments. Hastelloy C276 excels in high-temperature and highly corrosive environments due to its complex chemical composition, but this also comes with a higher cost. The choice between these alloys depends on specific application requirements and budget constraints.

content is empty!