| Availability: | |

|---|---|

| Quantity: | |

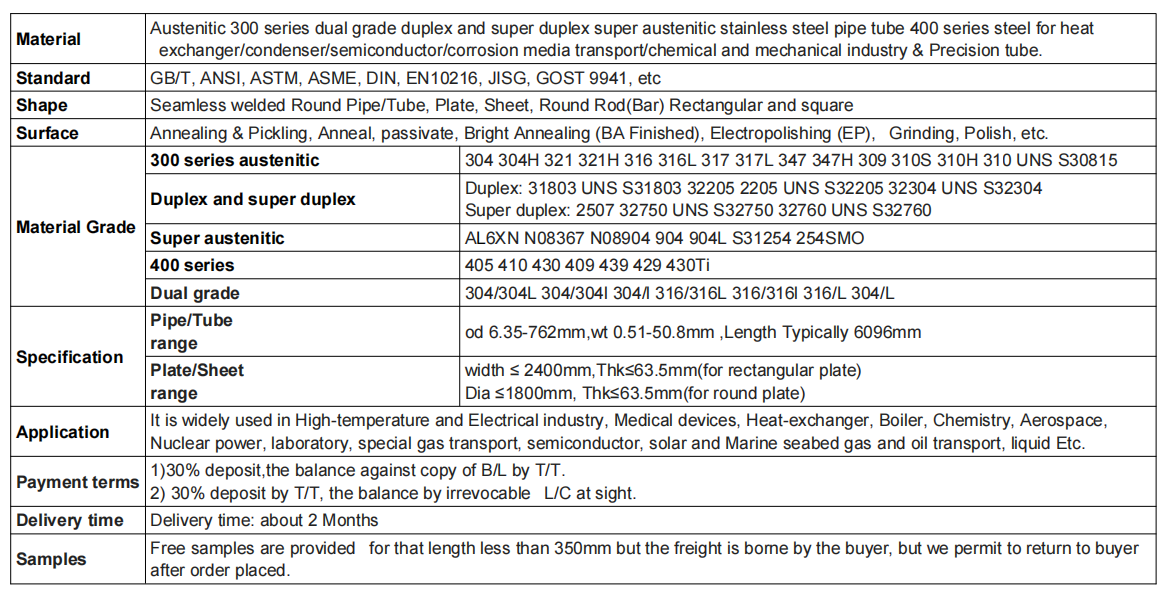

316Ti: A common abbreviation indicating a titanium-containing modification of 316 stainless steel.

S31635: The US UNS number (Unified Numbering System) is the only standard designation for this material.

Type: Austenitic stainless steel.

Core Improvement: Based on standard 316 stainless steel, titanium (Ti) is added (typically ≥5×C%, but ≤0.70%).

The core value of 316Ti (S31635) stainless steel pipe lies in its excellent resistance to intergranular corrosion, imparted by titanium stabilization, especially in the welded state or after moderate heating. While retaining the excellent overall performance of standard 316 stainless steel (general corrosion resistance, pitting corrosion resistance, formability, and weldability), it addresses the key challenges of welding and high-temperature service. This makes it a preferred material for piping systems in the chemical, petrochemical, and energy (boilers, heat exchangers), requiring welded structures and potentially exposed to corrosive media or moderate-to-high-temperature environments.

Mo | C | Si | Mn | P | S | Cr | Ni | Ti |

2.00-3.00 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 5x(C+N)-0.70 |

Tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) |

≥ 515 | ≥ 205 | ≥35 |

Density:7.98 g/cm³

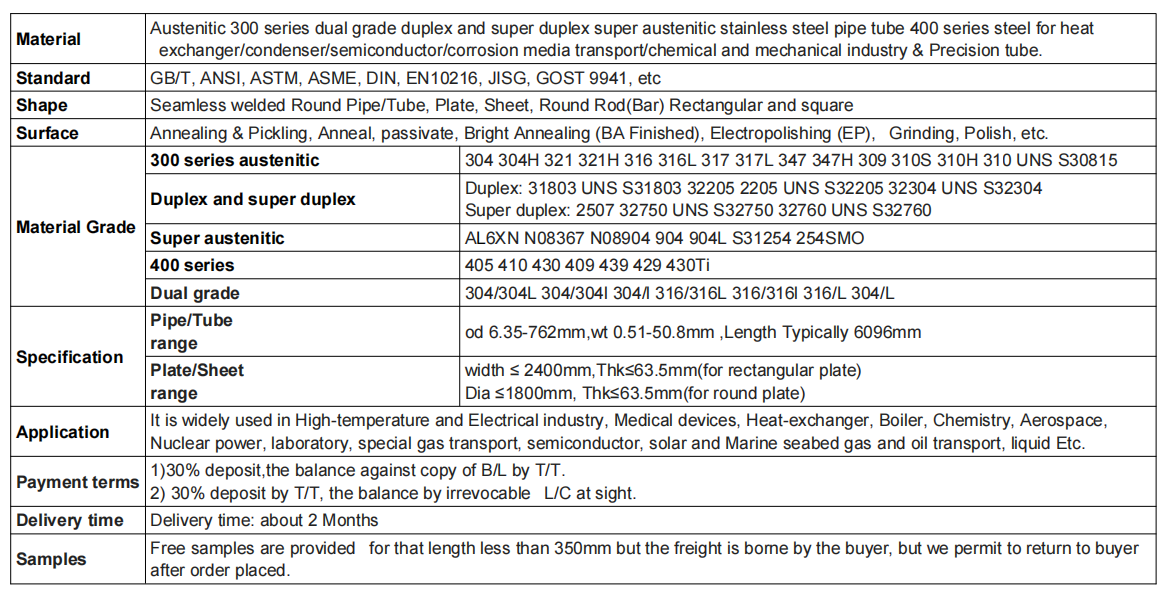

316Ti: A common abbreviation indicating a titanium-containing modification of 316 stainless steel.

S31635: The US UNS number (Unified Numbering System) is the only standard designation for this material.

Type: Austenitic stainless steel.

Core Improvement: Based on standard 316 stainless steel, titanium (Ti) is added (typically ≥5×C%, but ≤0.70%).

The core value of 316Ti (S31635) stainless steel pipe lies in its excellent resistance to intergranular corrosion, imparted by titanium stabilization, especially in the welded state or after moderate heating. While retaining the excellent overall performance of standard 316 stainless steel (general corrosion resistance, pitting corrosion resistance, formability, and weldability), it addresses the key challenges of welding and high-temperature service. This makes it a preferred material for piping systems in the chemical, petrochemical, and energy (boilers, heat exchangers), requiring welded structures and potentially exposed to corrosive media or moderate-to-high-temperature environments.

Mo | C | Si | Mn | P | S | Cr | Ni | Ti |

2.00-3.00 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 5x(C+N)-0.70 |

Tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) |

≥ 515 | ≥ 205 | ≥35 |

Density:7.98 g/cm³

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.