| Availability: | |

|---|---|

| Quantity: | |

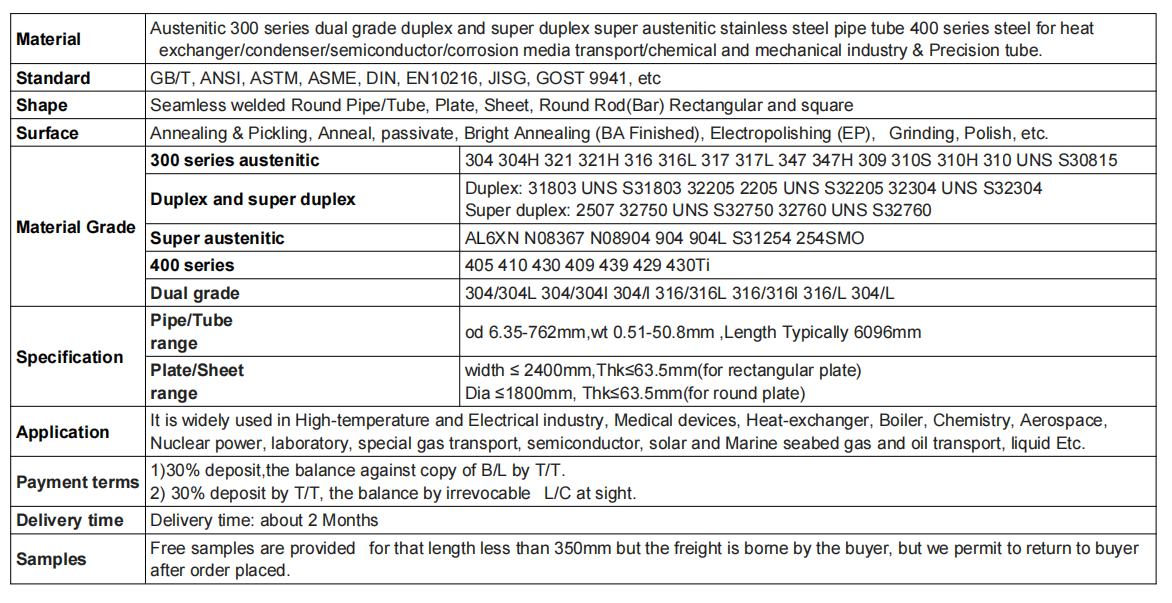

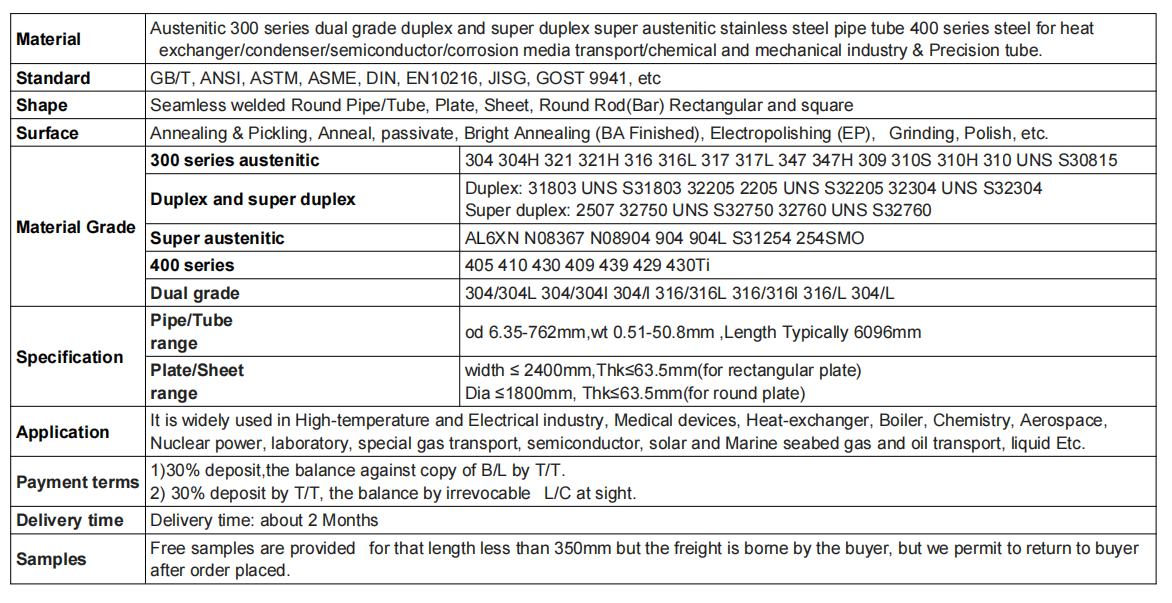

AL6XN (N08367) is a nitrogen-containing, high-molybdenum, high-chromium, high-nickel super-austenitic stainless steel. It represents one of the top corrosion-resistant alloys in the austenitic stainless steel family, designed to address extreme corrosive environments that standard austenitic stainless steels like 316L cannot withstand, particularly corrosion caused by chlorides (such as seawater, brine, and bleach) and acids (such as sulfuric and phosphoric acid). Its superior performance makes it more cost-competitive with nickel-based alloys such as Hastelloy C-276.

AL6XN (N08367) is a high-performance super-austenitic stainless steel that provides a robust solution for the most challenging corrosive environments, particularly those containing chlorides, while maintaining a cost advantage over nickel-based alloys. It has been widely and successfully applied in a variety of key industrial sectors, including marine, chemical, environmental, and energy. When selecting a material, a detailed evaluation must be conducted based on the specific media conditions, temperature, pressure, and design requirements.

C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N |

≤0.03 | ≤1.0 | ≤2.0 | ≤0.04 | ≤0.03 | 23.5―25.5 | 20―22 | 6―7 | ≤0.75 | 0.18―0.25 |

tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) | |

≥717 | ≥317 | ≥30 |

Density: 8.24g/cm3

AL6XN (N08367) is a nitrogen-containing, high-molybdenum, high-chromium, high-nickel super-austenitic stainless steel. It represents one of the top corrosion-resistant alloys in the austenitic stainless steel family, designed to address extreme corrosive environments that standard austenitic stainless steels like 316L cannot withstand, particularly corrosion caused by chlorides (such as seawater, brine, and bleach) and acids (such as sulfuric and phosphoric acid). Its superior performance makes it more cost-competitive with nickel-based alloys such as Hastelloy C-276.

AL6XN (N08367) is a high-performance super-austenitic stainless steel that provides a robust solution for the most challenging corrosive environments, particularly those containing chlorides, while maintaining a cost advantage over nickel-based alloys. It has been widely and successfully applied in a variety of key industrial sectors, including marine, chemical, environmental, and energy. When selecting a material, a detailed evaluation must be conducted based on the specific media conditions, temperature, pressure, and design requirements.

C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N |

≤0.03 | ≤1.0 | ≤2.0 | ≤0.04 | ≤0.03 | 23.5―25.5 | 20―22 | 6―7 | ≤0.75 | 0.18―0.25 |

tensile strength( Mpa) | 0.2% yield strength ( Mpa) | Elongation A5(%) | |

≥717 | ≥317 | ≥30 |

Density: 8.24g/cm3

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.

Company has 40 senior technicians, and meanwhile get the Quality Management Certification of ISO9001-2015 & PED 2014/68/EU and other related important certifications in industries. Such as DNV/ABS/TUV/Environment Management ISO 14001:2015/OHSMS Certification/Production License of Special Equipment P.R.C./US ASME Quality system certification and other Technology & Innovative Achievement Rewards.